Introduction

Connectors, also known as connectors, plugs, or sockets, are essential components used to establish electrical connections between active devices, enabling the transmission of electric currents or signals. As electronics professionals, we interact with connectors regularly, as they play a crucial role in modern electronic engineering.

This article aims to enhance our understanding the differences between FFC (Flexible Flat Cable) connectors and FPC (Flexible Printed Circuit) connectors, along with their common types.

A Brief Introduction to Connectors

Connectors serve a simple yet vital purpose: bridging gaps or isolations in a circuit to facilitate the smooth flow of electric current, enabling circuits to perform their intended functions. They are indispensable components in electronic devices, and one can find one or more connectors in almost every electrical circuit. Connectors come in diverse forms and structures, varying according to their application, frequency, power, and environmental conditions.

For instance, connectors used in lighting fixtures on a sports field vastly differ from those employed in hard disk drives or rocket ignition systems. Regardless of the connector type, ensuring an uninterrupted and reliable flow of current is essential. While connectors are traditionally associated with electric currents, they also find use in optical systems, where they facilitate the transmission of light signals through optical fibers, serving the same purpose as electrical connectors. For the purposes of this article, we will focus on electrical connectors and their applications, with a particular emphasis on products offered by Molex.

Differences between FFC Connectors and FPC Connectors and their Common Types

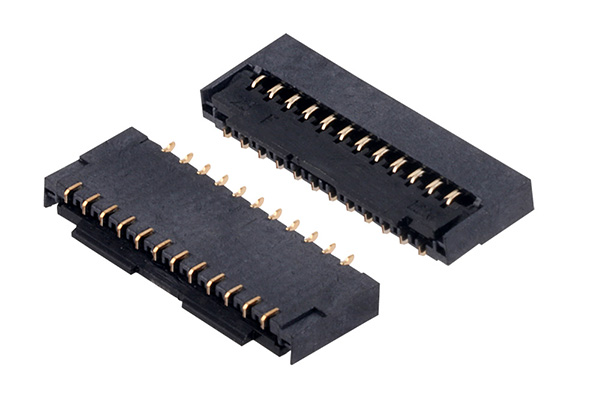

In the ever-changing landscape of connectors, diverse forms, and structures have emerged to cater to different applications, frequencies, power levels, and environmental conditions. FFC connectors are flexible flat cable connectors, which are novel data cable assemblies produced using PET insulation material and ultra-thin tin-plated flat copper conductors.

These highly flexible connectors allow easy bending, folding, and a low-profile design. They are known for their ease of use, quick connection and disconnection, and effective electromagnetic interference shielding (EMI). Now, let’s explore the differences between FFC connectors and FPC connectors, along with the common types of FFC connectors.

2.1 Differences between FFC Connectors and FPC Connectors

FFC connectors and FPC connectors differ in the way their circuits are formed:

- FFC connectors are constructed by sandwiching flat copper foil between two layers of insulation film, resulting in a relatively simple and thicker product.

- On the other hand, FPC connectors utilize chemical etching to shape Flexible Copper Clad Laminate (FCCL) into various types of flexible circuit boards, including single-sided, double-sided, and multi-layer structures.

Considering the production cost, FFC connectors are generally more cost-effective, making them a preferred choice for many companies.

Common Types of FFC Connectors

There are seven common types of FFC connectors:

A-type: Both ends are connected, and reinforcing plates are adhered to the insulation paper.

B-type: Reinforcing plates intersect and are directly adhered to the insulation paper.

C-type: Reinforcing plates are directly adhered to the conductors on both ends.

D-type: Reinforcing plates intersect and are directly adhered to the conductors on both ends.

E-type: One end has a reinforcing plate adhered to the insulation paper, while the other end is directly soldered.

F-type: Reinforcing plates are directly adhered to the insulation paper on both ends, with half of the internal area stripped.

G-type: Both ends are directly soldered.

Conclusion

As the field of connectors continues to evolve, several trends have emerged, including high-speed and digital signal transmission, signal integration, miniaturization of products, cost reduction, surface mount contact termination, modular assembly, and user-friendly plug-and-play features.

Understanding the differences between connectors like FFC and FPC allows us to make informed decisions when designing electronic systems, ensuring optimal performance and reliability. Connectors might seem like small components, but their significance in electronics and modern living is immeasurable, as they provide the vital links that power our interconnected world.